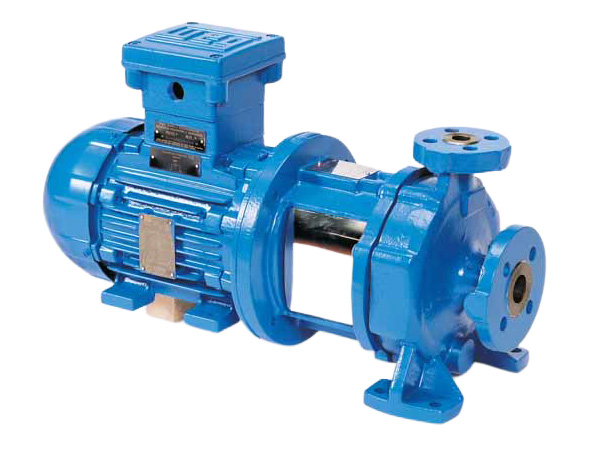

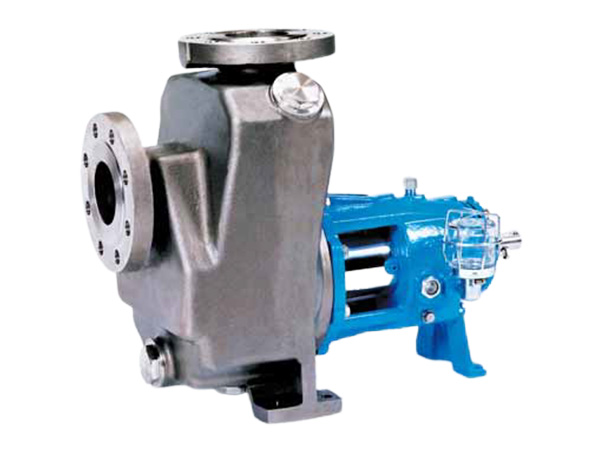

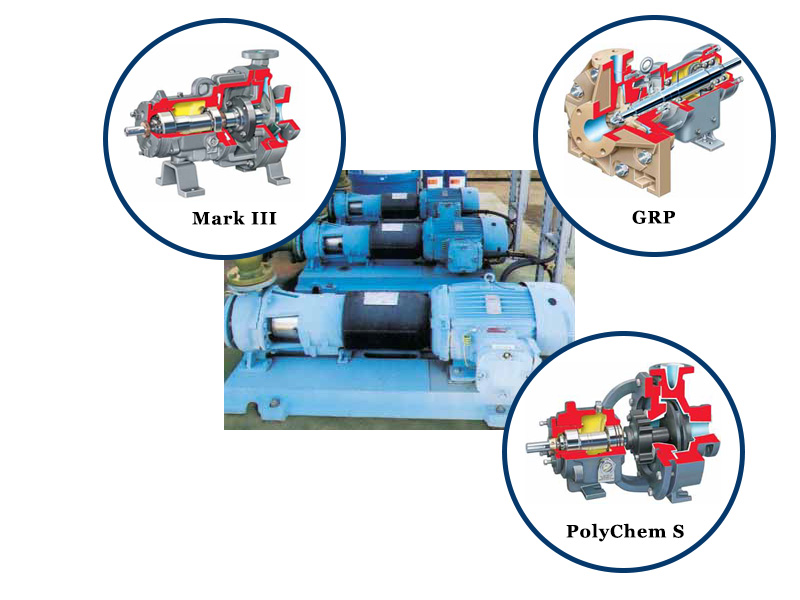

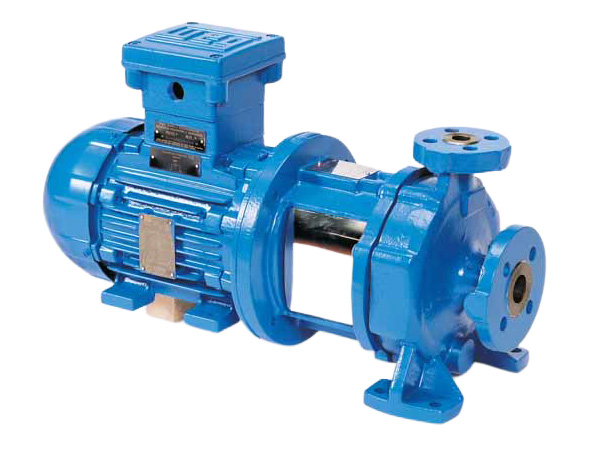

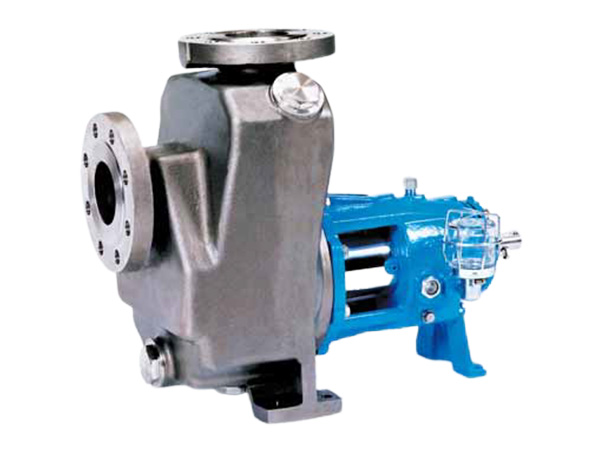

The CPX family of ISO chemical process pumps offers a wide range of configurations including mechanically sealed, magnetically driven, self-priming, close coupled and vertical pumps. The CPX family, therefore, offers unmatched flexibility and breadth of pumping solutions in countless applications.

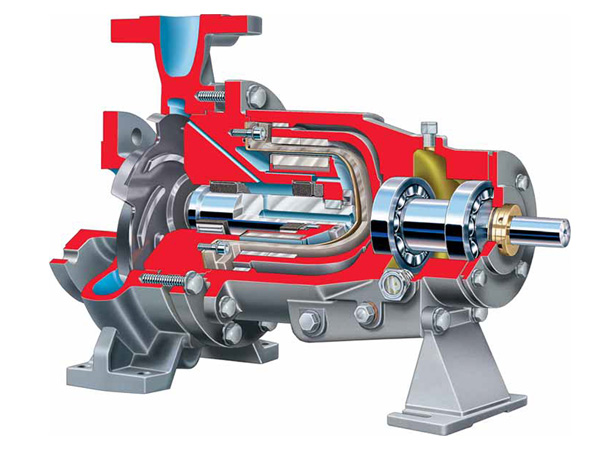

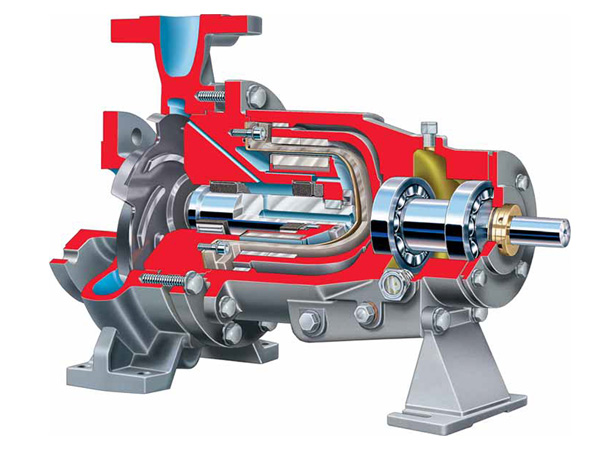

Commonality among the different pump configurations is a key benefit of the CPX family. All CPX pumps share the same state-of-the-art hydraulics, sealing options, and bearing frame options. This interchangeability translates into inventory and maintenance costs savings.