Menu

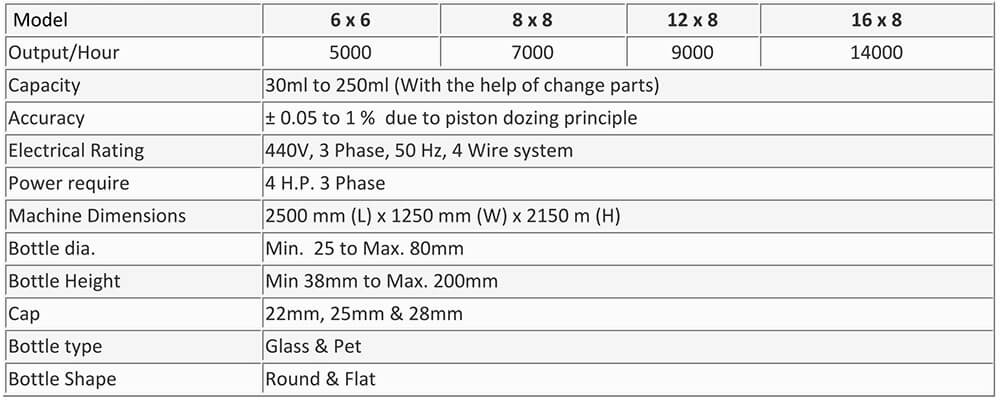

| Output / Hour | Upto 9000 Nos. of Round containers (Depending on the size of the container or the label) |

| Electrical Rating | |

| Main Motor | 1 H.P. 230 Volts 50 Hz |

| Vacuum Motor | 0.5 H.P. 415 Volts 50 Hz |

| Dimensions in mm | 3000 L X 1050 W X 1000 H (Wet Glue Labelling Machine) 1800 L X 1000 W X 1000 H (Sticker Labelling Machine) |

| Structure | Top stainless steel matt finish and MS body cladded in SS 304 sheet |

| Input Specifications Container Specification Label | 25mm to 80mm Dia. 38 to 200 Height Length 20mm to 150mm Width 16mm to 120mm. |

Rishikesh Exports